Value Stream Mapping

Many organizations

that have started down the “Lean Journey” have realized that improvement events

alone are not enough to take the organization to the next level of excellence,

productivity and efficiency. It also is not enough to embed a Lean culture in

the organization. Improvement events create localized improvements, however,

Lean tools such as Value Stream Mapping strengthens the gains obtained by

providing vision and plans that connect all improvement activities. Value Stream

Mapping has supporting methods that are often used by organizations to analyse

and design flows at the system level across multiple processes, or across

different departments.

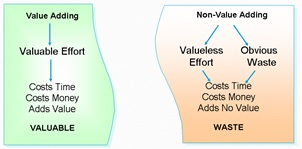

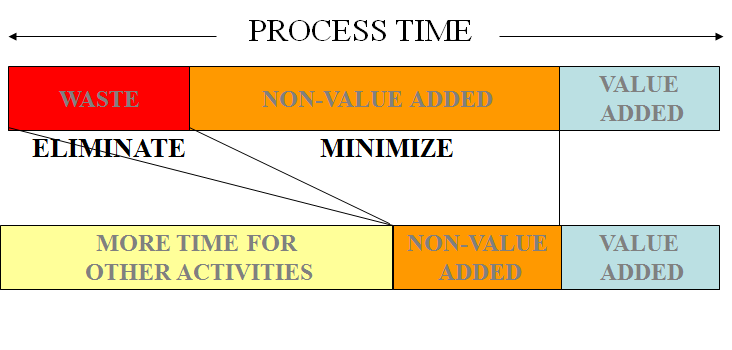

Our Value Stream Mapping Training course has been designed as a one-day programme so that your business can use it as the tool that allows you to see waste in manufacturing, production and business processes, and provides the foundation for the creation of plans to remove or streamline non-value-adding steps. This is achieved by analysing the current state and designing a future state for the series of events that take a product or service from its beginning through to the customer.

In Value Stream Mapping we follow a process from start to finish monitoring and measuring what happens within, and between, each process step. A flow diagram showing the process is drawn to reflect the current state of the operation. The non-value actions are identified in each step, and the process is analysed for opportunity to drastically reduce and simplify it to the fewest actions necessary.

By reducing wastefulness the redesigned process becomes more streamlined (the right things are being done) and more efficient (needing fewer resources). The reengineered process is flow charted in its future state with process steps and information flows redesigned, simplified and made less expensive.

Although value stream mapping is often associated with manufacturing, it is also used in logistics, supply chain, service related industries, healthcare, software development, product development, administrative and office processes.

This one-day, highly interactive workshop will provide you with all the skills you need to use the Value Stream Mapping approach to make your processes more efficient.

Delegates will analyse a real process as they go through the learning of all the individual tools. High emphasis is also placed upon the soft skills of team working, as it is in this area that the high impact benefits are won or lost.

This means that, on the day, every delegate will have used Value Stream Mapping to map the current state of a real process, identify waste in the process, and apply the tools to map the future state streamlining the process and achieving greater efficiency and productivity, thus building knowledge and confidence to lead and participate in mapping processes back at your organisation.

This workshop can also be delivered in-house as a stand-alone training workshop or integrated into wider improvement activities.

We are happy to discuss Value Stream Mapping in the context of your own business needs, so please contact us via email at compete@cforc.org or phone +44 (0)28 9073 7950 or our Dublin office +353 8 7224 2575 for more information.