Lean 101 - Fundamentals of Lean Manufacturing

This

training course has been designed for individuals and teams that want to gain a

better understanding of the tools and underlying philosophy of lean, and how

these elements and philosophy work together to create a Lean Organization.

Lean

is based on delivering two fundamental objectives: Customer satisfaction and

generating a profit. To achieve this, lean focuses on the

development of a continuous improvement culture, rooted in a fundamental

respect for people. It is a way of thinking, and a set of behaviours shaped by

Lean principles and the implementation of Lean tools.

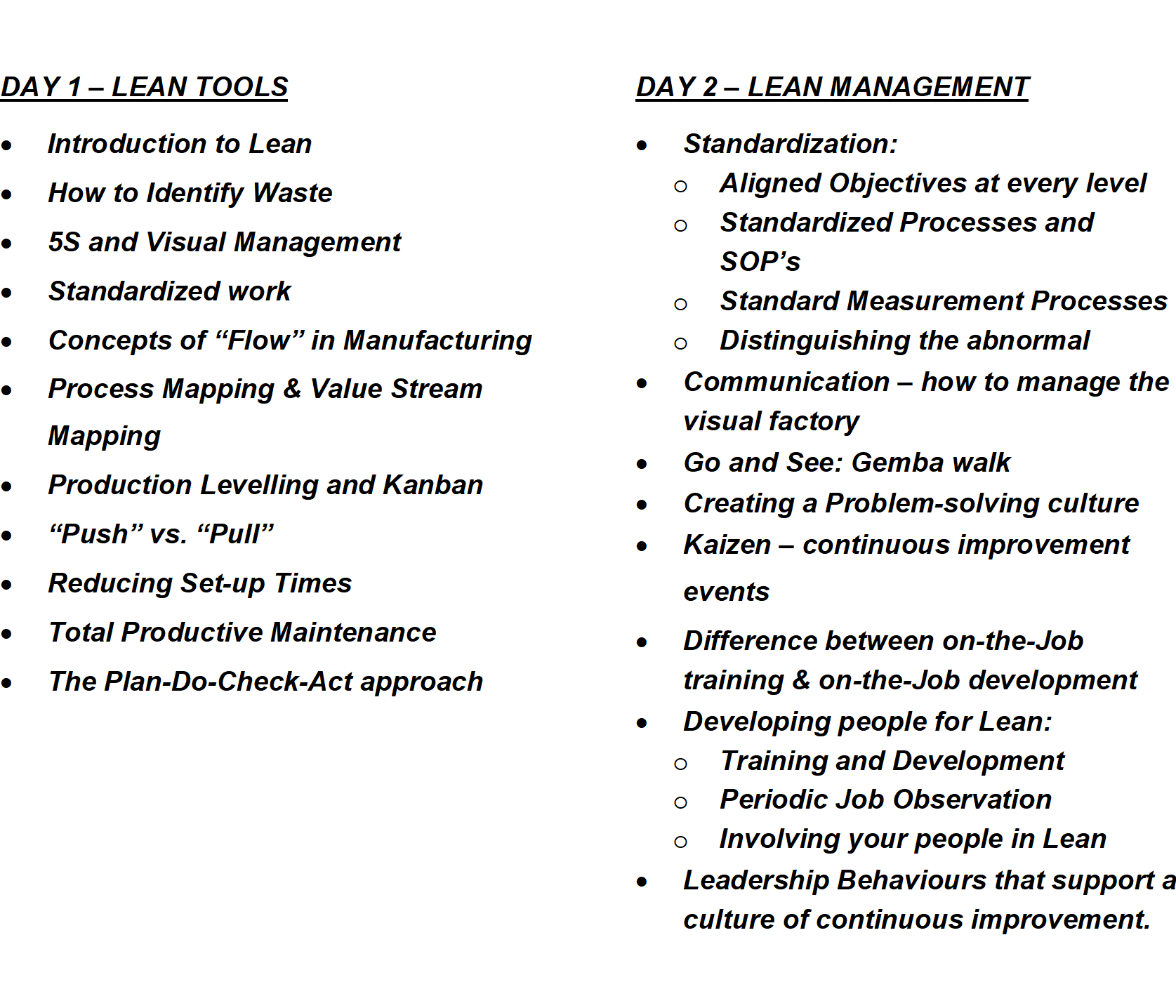

On Day

one of this programme you will learn the basic concepts of lean, and how to

implement these lean techniques and tools to help your organization remain

competitive, innovative, and profitable in today’s business environment.

Day

two focuses on how to deploy and manage Lean in your organization by involving

all your employees in the journey of improvement. Lean organizations see their

workforce as their greatest asset and seek to harness the power and creativity

of this resource in improving their workplace.

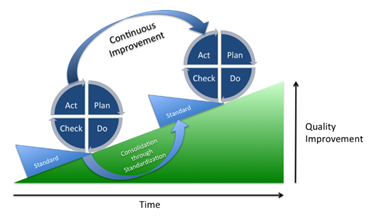

Throughout the training we will be applying the PDCA

approach to continuous improvement. It is known as a system for developing

critical thinking. At Toyota this is also known as "Building people before

building cars." Toyota and other Lean companies have proved that an

engaged, problem-solving workforce using PDCA is better able to innovate and

stay ahead of the competition through rigorous problem solving and the

subsequent innovations.

This course builds on these principles and will provide

participants with a structured method to manage change, using Lean Tools to

identify opportunities for improvement, processes to test and validate the

proposed improvements, and how to implement and sustain them. Then build upon

the improvement achieved to further improve using the PDCA cycle time and time

again.

This

workshop is usually delivered in-house as a stand-alone training workshop and

can be tailored to your organization’s context or integrated into wider

improvement activities.

It’s

structure also facilitates the delivery of the “Day 1 - Lean Tools” module only

if this is more aligned to the participants involved.

We will be happy to discuss our Fundamentals of Lean Manufacturing course in the context of your own business needs, so please contact us via email at compete@cforc.org or phone +44 (0)28 9073 7950 or our Dublin office +353 8 7224 2575 for more information.